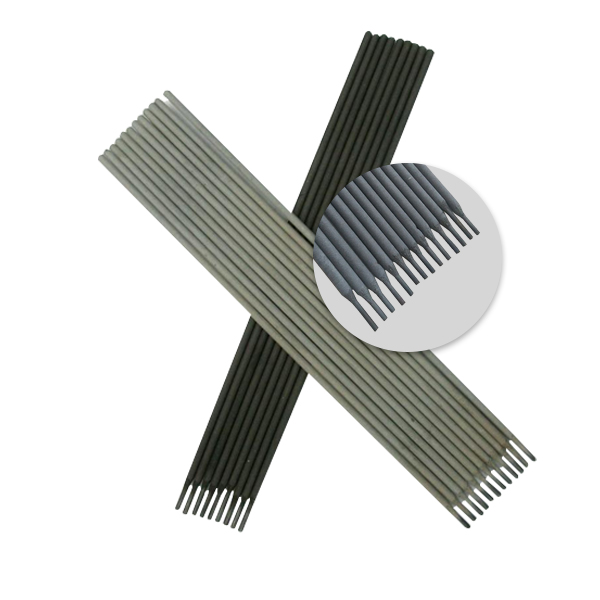

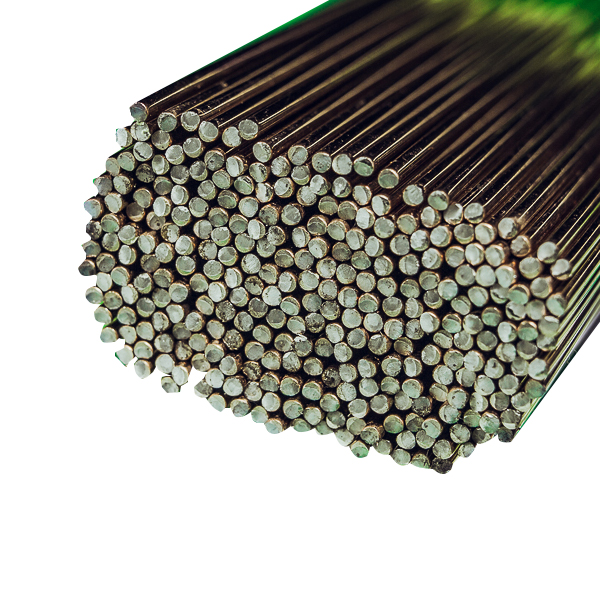

Nga tira waro teitei Te hiko a-ringa E9818-G Nga mahi Soldering

KAUPAPA KAUPAPA:

| KONO(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| Nga Ture AWS | - | - | - | - | - | - | - | - | - | - |

| UARA TAUIRA | 0.050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0.005 | 0.004 | 0.018 | 0.004 |

TE KAUPAPA MAHI:

| WHAI | KAUPAPA KAUPAPA(MPa) | TE KAUPAPA KAUPAPA(MPa) | WHAKAMAHI ℃xh | WARA WHAKAMAHI J/℃ | WHAKARANGA(%) | |||||

| GB/T RULES | - | - | - | - | - | |||||

| Nga Ture AWS | - | - | - | - | - | |||||

| UARA TAUIRA | 915 | 992 | - | 65/-20 | 16 | |||||

NGĀ TAWHE WELDING E WHAKATAHIngia ana:

| NGĀ WHAKATAKITANGA (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| TE HIKO (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

980Mpa kaha teitei iti ferrohydrogen paura momo iti koranu maitai hiko.

Pewa pumau, paku paku, pai te tango para

He pai te mahi fehokotaki mo nga tuunga katoa, he pai te pakari o te pāmahana iti, te aukati kapiti me te kaha o te paanga o te pāmahana iti.

KAUPAPA KAUPAPA:

| KONO(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| Nga Ture AWS | - | - | - | - | - | - | - | - | - | - |

| UARA TAUIRA | 0.050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0.005 | 0.004 | 0.018 | 0.004 |

TE KAUPAPA MAHI:

| WHAI | KAUPAPA KAUPAPA(MPa) | TE KAUPAPA KAUPAPA(MPa) | WHAKAMAHI ℃xh | WARA WHAKAMAHI J/℃ | WHAKARANGA(%) | |||||

| GB/T RULES | - | - | - | - | - | |||||

| Nga Ture AWS | - | - | - | - | - | |||||

| UARA TAUIRA | 915 | 992 | - | 65/-20 | 16 | |||||

NGĀ TAWHE WELDING E WHAKATAHIngia ana:

| NGĀ WHAKATAKITANGA (mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| TE HIKO (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

Tuhia to korero ki konei ka tukuna mai ki a matou