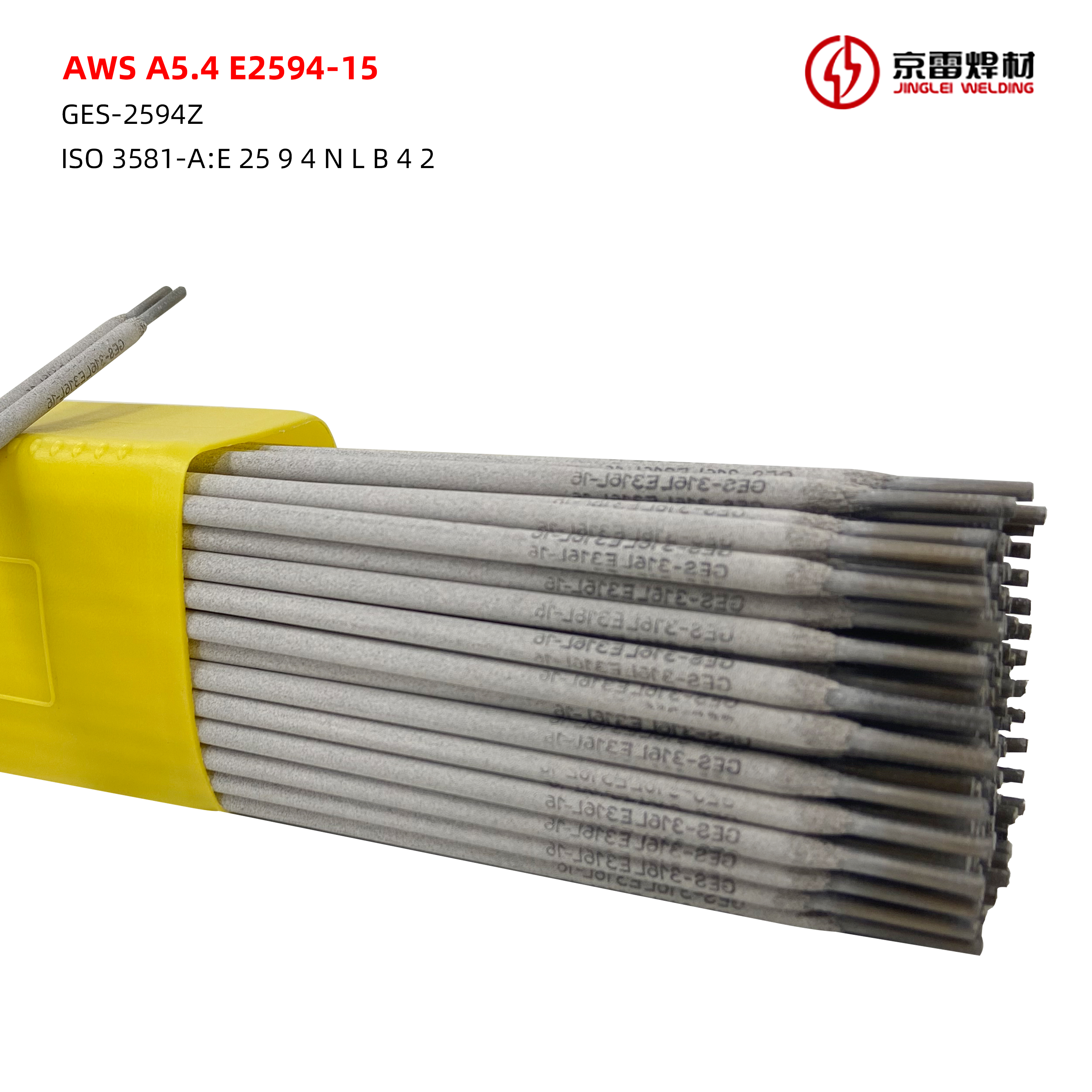

Kowiri tira Hiko A-ringa E2594-15 GXHY methanol dehydration pourewa hiko

HANGARAU WELDING

Kaua e tukua nga patai

Ka mau tonu ki a koe

Te koretake o te pewa

Te hanga hangai kino

Te kohukohu nui

He pai mo te whakapiri i te kowiri tira matarua

kei roto te 25% Cr, penei i te 0022 crni7mo4n03cr25ni6mo3cu2n, etc.

Ko te hauwai iti-waahanga rua kowiri tira hiko hiko, ko te waahanga matua ko 25.5Cr-10Ni-4Mo-0.25N

Ripple pai

Ko te konganuku weld he austenitic and ferritic biphase

hanganga, me te taupū ātete waikura ko PRE>40

He kaha teitei, he pai te atete ki te rua me te ahotea te pakaruhanga waikura.

He pai te hangarau whakapiri, he pewa pumau, he ataahua te hanga, he ripple ngawari, he pakaru iti, he ngawari te tango para.

Te tapawha ngawari

Tawhā Hua

KAUPAPA KAUPAPA:

| KONO(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Ētahi atu |

| GB/T RULES | 0.033 | 1.05 | 0.76 | 0.019 | 0.011 | 9.1 | 25.5 | 3.9 | 0.11 | N:0.24 |

TE KAUPAPA MAHI:

| WHAI | KAUPAPA KAUPAPA(MPa) | TE KAUPAPA KAUPAPA(MPa) | WARA WHAKAMAHI J/℃ | Te maimoatanga wera °C*h | ||||

| GB/T RULES | 918 | 22 | - | - | ||||

NGĀ TAWHE WELDING E WHAKATAHIngia ana:

| NGĀ WHAKATAKITANGA (mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| TE HIKO (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Tautoko wheketere

He pai te hua mo a

te whānuitanga o nga tono

HANGARAU WELDING

-

Ko nga taonga mo nga waka tereina

Harbin hiko toru kuwaha CMT

-

CJ50 whakawiri-ake

KAUPAPA KAUPAPA:

| KONO(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Ētahi atu |

| GB/T RULES | 0.033 | 1.05 | 0.76 | 0.019 | 0.011 | 9.1 | 25.5 | 3.9 | 0.11 | N:0.24 |

TE KAUPAPA MAHI:

| WHAI | KAUPAPA KAUPAPA(MPa) | TE KAUPAPA KAUPAPA(MPa) | WARA WHAKAMAHI J/℃ | Te maimoatanga wera °C*h | ||||

| GB/T RULES | 918 | 22 | - | - | ||||

NGĀ TAWHE WELDING E WHAKATAHIngia ana:

| NGĀ WHAKATAKITANGA (mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| TE HIKO (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||